About 1,500 years ago, someone in Persia watched the wind blowing and thought “I could do something with all that power”.

The windmill was the result of that observation and today, such mills are still being used

Prior to that time, only small quantities of corn could be ground, often using a pestle and mortar.

By harnessing wind power, large grinding stones could be developed and the quantities that could be ground at any time increased dramatically.

Wind power could also used to drive water pumps to drain low-lying swampy areas and to make them suitable for growing crops on previously unusable land, as in the Netherlands.

Such mills were also to be found at Prees in the early 16th century.

Apart from drainage uses, many villages in north Shropshire also had a wind-powered corn mill.

This saved the villagers from having to transport grain over poor roads, or to pay expensive tolls to get it to the nearest watermill. Whixall, Loppington, Cotonwood, and Bettisfield, just over the border in Maelor Saesneg, all had windmills catering for the corn and fertiliser grinding needs of local farmers.

The Loppington mill was built on a high ridge of ground in 1808, east of the lane leading to Brownheath Moss and three-quarter mile north-west of Loppington church.

It was very much a family business, once owned by Thomas Kynaston. He married Harriet, from Brentwood in Essex, and, on his death, she took over as miller. She died in 1878 and left the mill to their son, Thomas. He, his sister Mary, and his nephew ran the mill until his death in 1902.

He left £4,991 to his sister, proving that millers were not poverty-stricken! Milling carried on until at least 1908, but seems to have ceased shortly afterwards. The Whixall mill was at Stanley Green and was still working in the early 19th century.

The 1871 census shows George Shingler as the miller. However, the 1891 records show milling at Brains Hall with John Dawson operating the mill. By 1900, John Bostock appears to have taking over. The original windmill was demolished in 1930

The earliest windmills were simple ‘post-mills’ where the sails rotated from the top of a fixed pole.

The whole mill had to be turned into the wind in order to get the sails turning. This design was improved by the development of the ‘tower mill’. In this, a stone tower was built, with a rotating roof, to which the sails were attached, so that only the roof had to be turned.

When operating, sailcloth could be attached to the sails so that they caught the full power of the wind.

The arms were attached to a horizontal beam and from this, a system of cogwheels drove a vertical shaft which rotated a grindstone and ground the corn. Animal feedstuffs were ground at at Hawkstone Park.

Built by William Hazeldine of Moreton forge in about 1808, the mill was part of Sir Richard Hill’s Hawkstone Park estate.

Wind-powered mills had one major disadvantage in that they relied on the winds blowing continuously and in the north Shropshire area there were several former windmills which survived as a result of upgrading.

In the 19th century, with improved transport methods, coal could be brought in and some mills changed to steam power. Bettisfield witnessed many changes to the methods of power used by the mills.

Initially, it had a windmill which Reg Meredith of Bettisfield believes was built around 1790. In 1868 Edward and Sarah Hughes, whose family had previously run the windmill, replaced it with a steam mill. At a later date, the family updated the mill again and installed a diesel engine.

The last upgrade involved installing an electric system. It closed in 1990 and has now been converted to residential use.

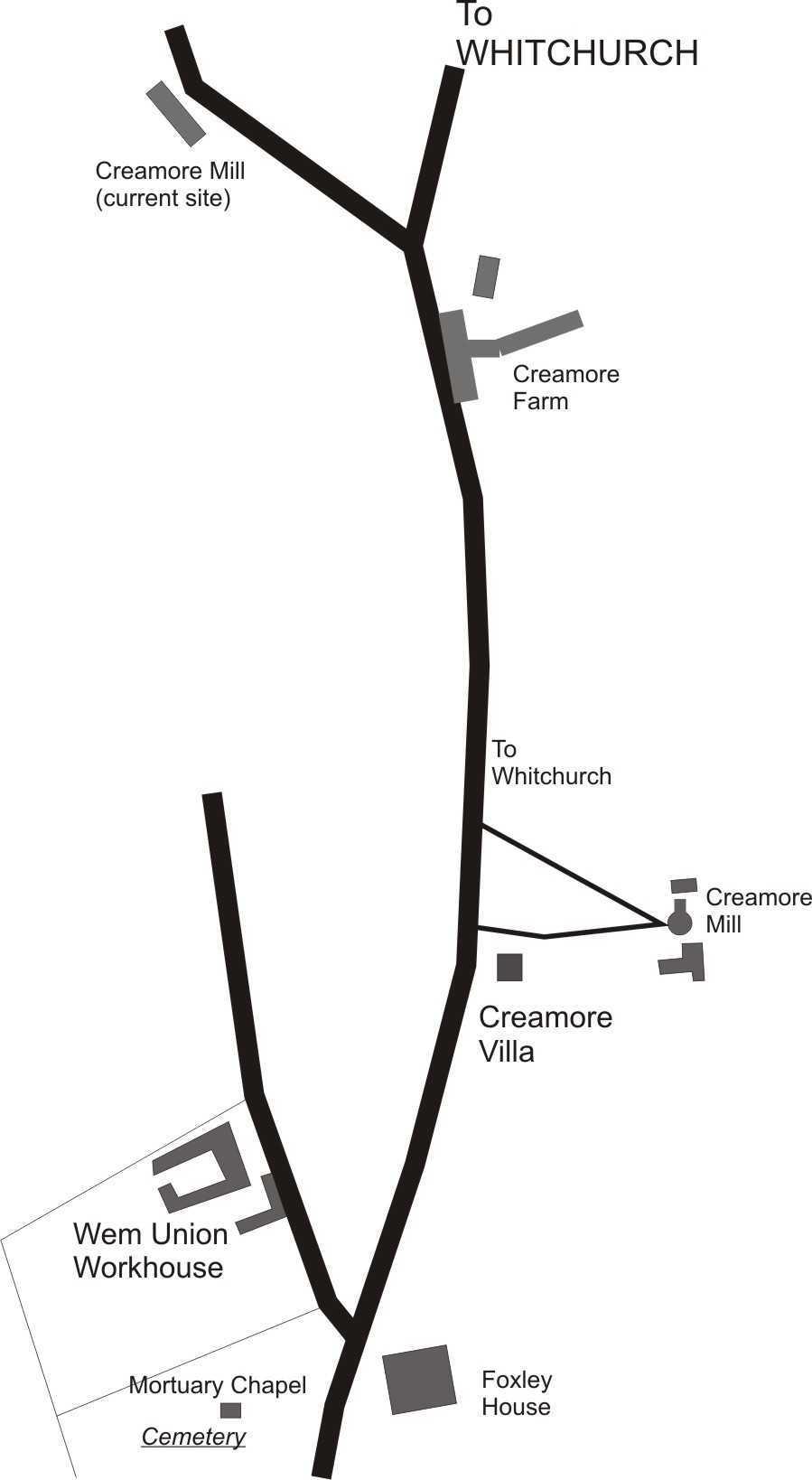

Similarly in Wem, there were both windmills and steam mills at Creamore. The original mill was a windmill at Creamore Villa and was mainly involved with grinding corn.

According to the historian Judith Everard, in her researches for the Victoria County History of Wem, the mill was established shortly before 1851 by Thomas Jebb, the son of a Whitchurch miller.

By 1871 Henry Hinton, a former employee, had taken over from Jebb as master miller. In 1875 it was described as a steam corn mill with a substantial residence and land.

At that time, it had three pairs of French stones driven by a 12-horse power steam engine.

By 1871, Jebb had retired from milling at the age of 41 and died in July 1875, leaving around £2,000. Hinton became master miller of Wem mill, and Creamore mill was in the hands of William Wycherley.

By 1891, Richard Wycherley was the miller and this family ownership continued into the 1930s. A 1932 map also shows a mill on Ryebank and it is this that is now known as Creamore Mill.

The mill behind Creamore Villa became Mill House Farm and at some stage in the 1930s ceased milling. The 1934 map shows the site in Ryebank as the mill at a farm owned by the Abbott brothers.

The Wem historian Tom Edwards remembers grain being taken there for milling in the 1950s.

It closed in 1960 after the death of one of the brothers and now houses a wood company.

Improvements in technology led to a rapid decline in the use of windmills. By 1895, only Morville and Loppington remained in all of Shropshire. By 1917, they too were gone. Wind power was seen to be outdated and the mills were demolished, or, as at Cotonwood and Hadnall, converted into private houses.

However, new windmills are springing up everywhere, providing a clean, reliable and future-proof source of electricity. In 2017 this provided 15 per cent of our electricity.

It is proof of the old saying that what goes around, comes around.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here